Scope

EMIS addresses the ever increasing challenges facing the oil and gas industry to maintain and boost the project technical and commercial feasibility. Besides the technical optimizations, our principals assist clients in setting out an optimum cost and implementation strategy.

Offshore

Onshore

Subsea & Pipelines

Floating Systems

The early stage development study of a project is always recognized by its high level of uncertainty and risks. It also presents the opportunity to bring the highest impact onthe project life cycle costs and risks. In our experience we have been able to exercise up to 30% cost reduction on the original concept by practicing our structured method, innovative thinking and lessons learnt.

Offshore

Solving today’s challenges in highly competitive business environment requires new perspective. Discover our capabilities and focus area in the Offshore section.

Minimum facility platforms

For development of marginally economic oil and gas fields there is greater urge for innovation in as many aspects of asset design, processes and development programs as possible. An unmanned Minimum Facility Platform can reduce both capital and operational costs of development as well as the time to first production. Easy installation of such facility often with topside and jacket as one piece provides a great advantage of reduced installation cost at lower risk.

This concept however shall be fully developed to consist of all production and transportation scenarios and correspondent investments. At EMIS we support our clients in developing such concept and investigating its suitability under the project specific conditions and the existing infrastructure in the area. Our team has successfully developed some of the most economic, safe and operationally flexible concepts for the marginal fields in the North Sea.

Asset optimization

Oil and Gas developments are capital intensive projects; improving productivity with increasing production and reducing costs are at the heart of maximizing the investments return. The industry’s challenge is to find the balance between marginal costs of modernization versus the increased safety and marginal gain of prolonged or increased production especially with the aging infrastructures.

EMIS provides innovative solutions based on its engineering experience and technical knowledge with diverse on- and offshore optimization projects to assist operating companies. Our project experiences cover the full spectrum of upgrading systems i.e. compression units, converting to normally unmanned installation (NUI), integrating new automation system, increasing recovery and developing bespoke production optimization tool. We also support our clients in life time extension projects to study and execute required modifications and assist in liaison with certification authorities.

Processing platforms

Often the primary optimum option to develop a new field is a full processing platform. The main technical driving factors include but are not limited to export product specification, transportation technical feasibility and challenges, suitability of receiving facility. Most importantly the capital and operating direct and indirect (third party) costs of processing, transportation and storage also strongly influence the choice of the platform type.

Typically, a Processing Platform consists of wellheads, separation equipment, oil stabilization, oil or gas dehydration, pumping or compressing units as well as utilities i.e. chemical injection, water treatment, fuel and power, venting and storage systems. Our professionals have been responsible for developing concept and FEED studies of number of processing platforms greenfield or brownfield modifications designed for shallow water.

Onshore

Solving today’s challenges in highly competitive business environment requires new perspective. Discover our capabilities and focus area in Onshore section

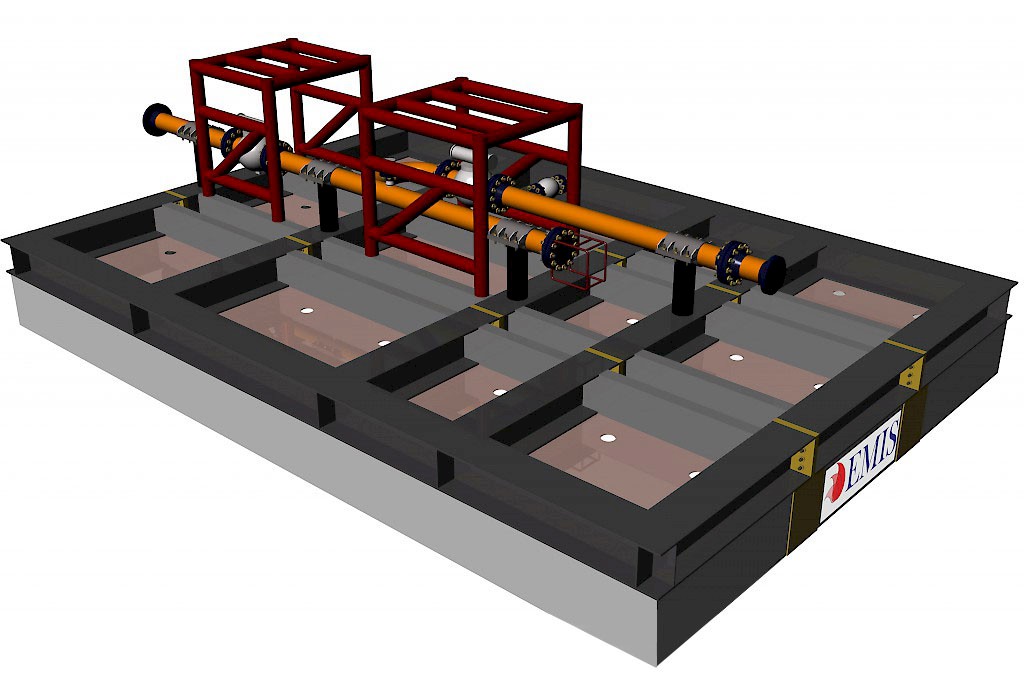

Oil Production Facility

Modular and simplified designs of oil production facilities require lower costs and have shorter lead time. Early production facilities offer a great advantage to operators to generate revenue for further development of the field while reducing the risks of suboptimal design. Standardized systems provide additional advantages of minimized engineering costs and timeline and better negotiated equipment price.

Our experience and expertise in design of oil production facilities encompass oil and gas separation systems, crude oil desalination and dehydration, oil stabilization, produced water treatment and injection, oil pumping station and integrated chemical injections skids.

LPG and NGL Recovery

Liquid recoveries have been primarily associated with large fields with high flowrates. Gas operators’ main focus often is to build a low cost production unit to extract the value of gas while producing heavier components at sideline. Marginal fields potentials of producing high value light liquids are occasionally overlooked.

Our professionals have successful track record of proving high economic value of additional investment on light liquid production in marginal fields. Through initial concept selection scope, we have identified and appraised over 20 various production configurations and evaluated their technical and commercial performances to conclude the best performing optimum and lean design. Our engineering team has been involved in Concept, FEED study of various NGL-LPG production facilities.

Gas Compression Facility

Subsea & Pipelines

Solving today’s challenges in highly competitive business environment requires new perspective. Discover our capabilities and focus area in Subsea & Pipelines section

Flow Assurance

One critical aspect in stable production is to ensure uninterrupted fluid transfer in the pipelines and availability of required systems to maintain smooth operation. The low cost concepts of Minimum Facility Platform and subsea Tie Backs require in depth analysis of multiphase transfer.

In our experience, both the project risks and costs are directly and strongly influenced by determining an optimum operating envelop for various development scenarios and operating conditions; steady state and dynamic at start and end of the field life. In multiple projects, our team of flow assurance experts have developed the most feasible pipeline and receiving facility designs as well as hydrate management and pigging strategies that led to significant risk and cost reduction. In these projects and in close collaboration with reservoir engineers we have optimized production flow and minimized the total cost of ownership.

Transmission Pipelines

Maintaining the integrity of the pipeline system throughout the design life requires significant knowledge and experience to prevent the costs of retrieving, maintenance and reinstallation and minimize the associated risks. Vulnerability of offshore installations to climate conditions has imposed greater additional risks and costs to such developments. Advanced knowledge and experience in pipeline engineering and installation are critical to tap the opportunity and minimize such costs and risks.

Our professionals bring years of invaluable experience and knowledge in pipeline and riser design to the project. From concept to detailed design EMIS engineers have developed innovative solutions for several complex projects in pipeline and riser designs and tie-in applications to life flowlines.

Subsea Structures

Surface facilities demand higher capital investment and enforce longer lead time. Often these result in underperforming economic metrics and consequently abandoning the development of marginal fields. Subsea structures are attractive and viable alternatives for surface facilities. However, overcoming technical challenges in design, safeguarding, installation, environmental impact and stability requires signification knowledge and experience.

At EMIS, we have accomplished design and development of standardized low cost solutions that can be applied across all prospects. The subsurface structure design has enabled development of economically challenging fields and provided subsea well tied back of a successful well to host infrastructure in the region. The subsea production unit design also provides an option for a daisy chain tie in to another subsea well and features a subsea HIPPS application.

Floating Systems

Solving today’s challenges in highly competitive business environment requires new perspective. Discover our capabilities and focus area in Floating Systems section

Installation Engineering

From concept to execution, well devised installation methods, advice and suitable engineering are critical to schedule and budget success of a project. There are often great opportunities to streamline installation and reduce cost, however, particular expertise is required to fully develop such installation concepts.

At EMIS, our professionals have worked at the core of challenging installation scopes from preliminary studies to detailed design and execution. They can add great value to installation scopes and overall concept development by drawing on years of overcoming technical challenges associated with loadouts, subsea lifts, floatovers and pipelay campaigns.

Mooring Study

Mooring is a specialized field where engineering design and seamanship practices are intertwined like few other. Designers need intimate knowledge of seamanship practice relevant to the mooring system to be able to deliver an efficient, safe and effective mooring solution. In addition, designers and analysists must take into account how the documentation they produce will be interpreted by the end user.

Through experience with most types of mooring systems, including permanent or temporary, in or outside sheltered waters, EMIS engineers have developed the practical understanding required to execute mooring engineering in ways that best suit the application.

Naval Architecture

At the heart of determining the feasibility of most streamlined or even slightly novel offshore installation campaign lie fundamental questions that only a seasoned Naval Architect can address. Vessel global strength, racking, satisfying stability regulations, flexure, vessel to vessel mooring, satisfying towing regulations and implication of Dynamic Positioning best practice are some examples of areas that require specific knowledge and thorough experience.

Having been exposed to expectations of clients around the world with regards to installation streamlining installation campaigns, the EMIS team are capable of performing Naval Architecture related investigations or provide advice as to the best ways of finding a solution.